Blister pack packaging is a type of packaging that is commonly used for small consumer goods, pharmaceuticals, and medical devices. It features a pre-formed plastic cavity or pocket, usually made of thermoformed plastic, which holds the product securely in place. This plastic cavity is often sealed to a paperboard backing or a plastic cover, providing a clear view of the product while protecting it from environmental factors like moisture and tampering.

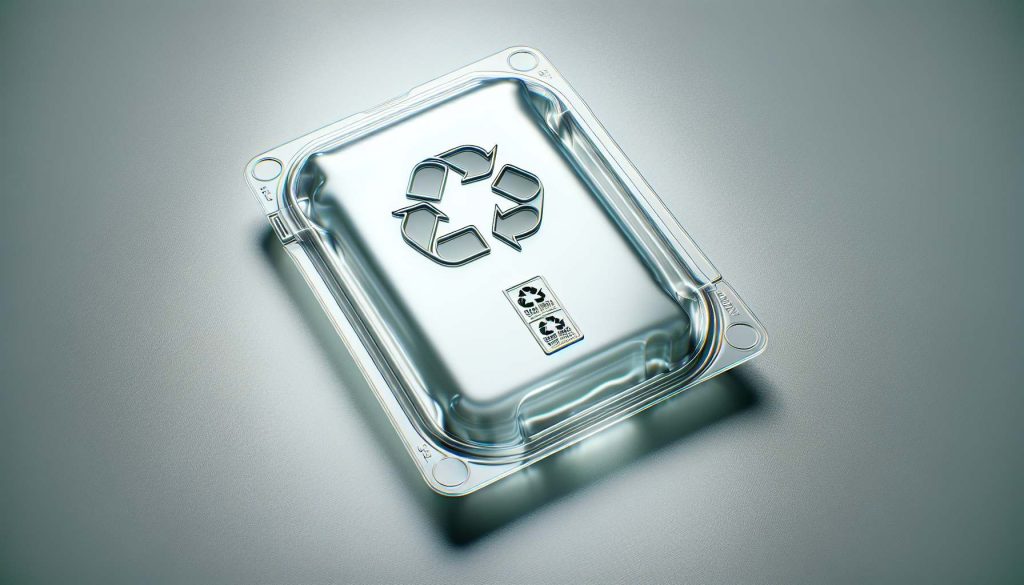

A clamshell package is a specific type of blister packaging that is composed of two halves (a front and a back) made of the same material, usually plastic, connected by a hinge. This hinge allows the package to open and close like a clamshell, hence the name. Clamshell packaging provides enhanced security and product visibility and is often used for electronics, tools, and other retail items.

Mini clamshell packaging refers to smaller versions of clamshell packages, used for packaging smaller items while still providing the same benefits of protection and visibility.

What products will use Blister pack packaging and clamshell package?

Blister pack packaging and clamshell packaging are used for a wide variety of products across different industries:

- Pharmaceuticals: Blister packs are commonly used for packaging medication, such as pills and capsules, providing protection and convenient dosing.

- Consumer Electronics: Clamshell packaging is often used for products like headphones, USB drives, and small electronic gadgets, offering protection and visibility.

- Toys and Games: Both blister and clamshell packaging are used to display toys and games, allowing consumers to see the product while keeping it secure.

- Hardware and Tools: Many small tools and hardware items are packaged in clamshells, providing durability and tamper evidence.

- Cosmetics and Personal Care: Items like razors, toothbrushes, and cosmetic products are often packaged in blister packs or clamshells to maintain hygiene and offer a clear view of the product.

- Office Supplies: Products such as pens, markers, and other stationery items are frequently packaged in blister packs for easy display and access.

Blister packaging types?

Blister packaging comes in several types, each designed to meet specific needs and preferences. Here are some common types of blister packaging:

- Face Seal Blister: In this type, the plastic blister is sealed to the surface of a cardboard backing. The plastic does not extend beyond the edges of the card, making it a cost-effective option for lightweight products.

- Full-Face Seal Blister: Similar to the face seal, but the plastic blister extends to the edges of the backing card, providing additional security and a more uniform appearance.

- Trapped Blister: This design involves the blister being sandwiched between two cards. This type is often used for heavier products, as it provides additional support.

- Slide Blister: The product is placed in a blister, which is then slid into a card. This allows for easy access to the product without damaging the packaging.

- Clamshell Blister: A type of blister packaging that folds onto itself and is usually sealed around the edges. It’s often used for products that require extra security and protection.

What is the advantages and disadvantages of blister pack packaging

Blister packaging offers several advantages and disadvantages, which can help determine its suitability for different products and industries:

Advantages:

- Product Protection: Blister packaging provides excellent protection from environmental factors such as moisture, light, and contamination, ensuring that products remain safe and intact1.

- Tamper Evident: It offers a clear view of the product and provides a tamper-evident seal, which helps ensure product integrity and consumer safety2.

- Product Visibility: The transparent plastic allows consumers to see the product without opening the package, which can enhance customer confidence and increase sales3.

- Cost-Effective: For high-volume production, blister packaging can be a cost-effective option due to its relatively low material and production costs4.

- Portability: Blister packs are lightweight and portable, making them convenient for consumers5.

Disadvantages:

- Environmental Impact: Blister packaging, especially those using non-recyclable plastics, can have a negative environmental impact due to the difficulty of recycling some materials1.

- Initial Costs: The setup and tooling costs for blister packaging production can be high, which may not be cost-effective for small production runs2.

- Accessibility: Blister packs are sometimes difficult to open, which can lead to consumer frustration, especially among elderly or disabled individuals3.

- Design Limitations: While effective for many products, blister packaging may not be suitable for irregularly shaped items that require custom molds4.

These factors should be considered when deciding whether blister packaging is the right choice for a particular product5.

How to order and customize blister pack packaging?

Customizing and purchasing blister packaging involves several steps, from design to supplier selection. Here’s a detailed guide based on available resources:

- Determine Your Requirements: Identify the specific needs for your blister packaging, including the type of product, size, and any special features or branding elements you want to include.

- Design Customization: Work on the design aspects of your blister packaging. This can include special finishes like matte or gloss, embossing, or spot UV coating to enhance the visual appeal. You may need to collaborate with a packaging designer from supplier like an Engineering Assistant from packagingcc.com to create a suitable design

- Choose a Supplier: Research suppliers or manufacturers that specialize in custom blister packaging. Look for those with experience in your industry and check their portfolio and customer reviews.

- Request Quotes and Samples: Contact potential suppliers to discuss your design and get quotes. Request samples to ensure the quality meets your expectations before committing to a large order.

- Negotiate Terms: Discuss terms and conditions with the supplier, including pricing, delivery schedules, and payment terms. Make sure to clarify any doubts you may have.

- Finalize the Design: Work closely with the supplier to finalize the design, ensuring it accurately represents your brand and meets all functional requirements.

- Place the Order: Once you are satisfied with the design and terms, place your order. Provide all necessary details to avoid any misunderstandings.

- Monitor Production: Keep in touch with your supplier during the production process to ensure everything is on track and address any potential issues quickly.

- Delivery and Evaluation: Once the blister packs are delivered, evaluate them to ensure they meet your specifications and expectations. This is also a good time to establish a long-term relationship with the supplier for future orders.

For more detailed information, you can contact us by packagingcc.com and A packaging specialist will follow up on your inquiry.

Whatsapp: https://wa.me/+8613570649762

Telegram: https://t.me/packagingcc