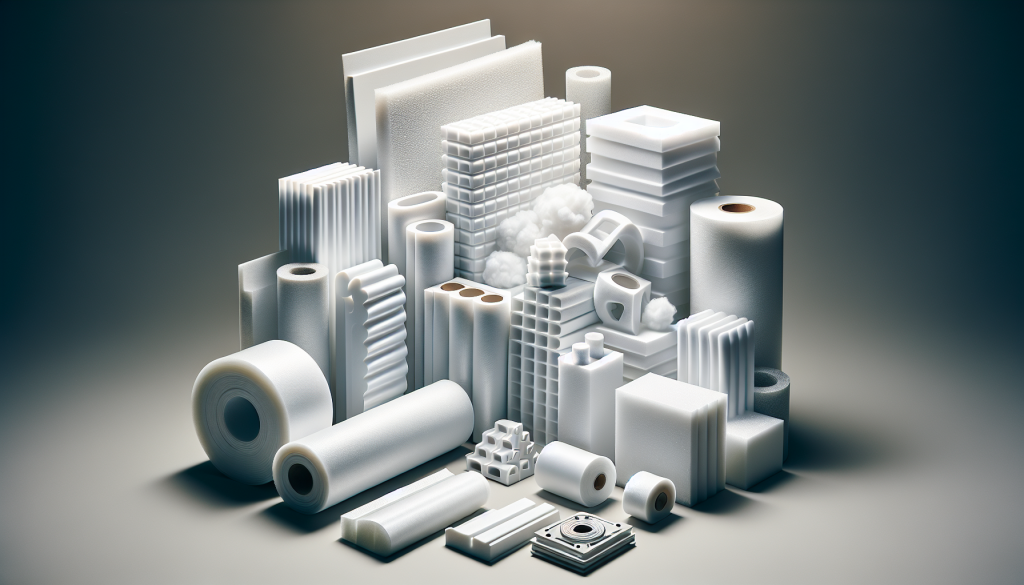

EVA foam packaging is a versatile and protective material used widely across various industries for safeguarding products during storage and transportation. Known for its excellent cushioning properties, EVA foam packaging is an integral component in ensuring the safety and integrity of items, ranging from electronics to delicate instruments. This article explores the material process and diverse applications of EVA foam packaging in detail.

Material Process of EVA Foam Packaging

EVA foam packaging is made from ethylene-vinyl acetate (EVA), a copolymer that combines ethylene and vinyl acetate. The material is known for its flexibility, resilience, and stress-crack resistance, making it an ideal choice for protective packaging solutions.

The process of creating EVA foam packaging begins with the polymerization of ethylene and vinyl acetate. The resulting copolymer is then mixed with various additives to enhance its properties, such as UV resistance, flame retardance, or coloration. The mixture is then subjected to a foaming process, typically involving heat and pressure, which expands the material into a lightweight, closed-cell foam. This foam can be molded, cut, or shaped into various forms to suit specific packaging needs, offering custom solutions for different products.

Characteristics of EVA Foam Packaging

EVA foam packaging is characterized by its softness, flexibility, and shock absorption capabilities. These attributes make it a popular choice for packaging sensitive and fragile items. The closed-cell structure of EVA foam packaging provides excellent moisture resistance, protecting products from environmental factors like humidity and water exposure. Additionally, EVA foam packaging is non-toxic and odorless, making it safe for use with consumer goods and food products.

Applications of EVA Foam Packaging

EVA foam packaging is employed in a wide array of industries due to its versatility and protective qualities. Here are some common applications:

- –Electronics:

In the electronics industry, EVA foam packaging is used to cushion and protect delicate components such as circuit boards, smartphones, and computer parts. Its anti-static properties prevent damage from electrostatic discharge, ensuring the safe transport and storage of sensitive equipment.

- -Automotive:

EVA foam packaging is utilized in the automotive sector to protect parts and components during shipping. Its shock-absorbing properties make it ideal for safeguarding items like headlights, mirrors, and interior panels from damage during transit.

- -Medical Instruments:

In the medical field, EVA foam packaging is used to secure and protect delicate instruments and devices. Its clean and non-toxic properties ensure that medical products remain uncontaminated and safe for use.

- -Consumer Goods:

Many consumer goods, such as toys, sporting equipment, and footwear, benefit from EVA foam packaging. Its lightweight nature and ability to be custom-shaped make it perfect for packaging items that require specific forms and dimensions.

- -Food and Beverage:

EVA foam packaging is also used in the food and beverage industry for its moisture resistance and non-toxic properties. It can be used to insulate and protect perishable items, ensuring they arrive fresh and intact.

Benefits of EVA Foam Packaging

EVA foam packaging offers numerous advantages, making it a preferred choice for many applications. Its lightweight nature reduces shipping costs, while its durability ensures long-lasting protection for products. The material’s flexibility allows it to be easily customized to fit a wide range of shapes and sizes, providing tailored solutions for specific packaging needs. Additionally, EVA foam packaging is recyclable, making it an environmentally friendly option compared to other packaging materials.

Conclusion

EVA foam packaging is an innovative and effective solution for protecting products across various industries. Its unique combination of flexibility, resilience, and protective qualities make it an essential material for ensuring the safe transport and storage of goods. By understanding the material process and diverse applications of EVA foam packaging, businesses can make informed decisions about their packaging needs and enhance the safety and integrity of their products. Whether for electronics, automotive components, or consumer goods, EVA foam packaging remains a reliable and versatile choice for safeguarding valuable items.

Whatsapp: https://wa.me/+8613570649762

Telegram: https://t.me/packagingcc